Home

Home /

Products /

Programmable high and low temperature humid tester

Programmable high and low temperature humid tester

The constant temperature and humidity machine is to simulate high and low temperature operation & storage, temperature cycling, high temperature and humidity, low temperature and humidity, condensation test, etc of products under combined conditions of climate and environmental temperature and humidity so as to inspect whether the adaptability and characteristics of the products change.

Requirements of international standards (IEC, JIS, GB, MIL ...) shall be met to achieve the consistency of measurement procedures (including testing procedures, conditions, methods).

1. Advanced and reliable refrigeration system:

■European and American totally-enclosed compressor imported with original packing

■adopt imported environmental protection cooling media (R507, R404A or R23)

■have the refrigeration components and high efficiency cold and heat exchange system with the most famous brand in the world

■excellent process and low failure rate

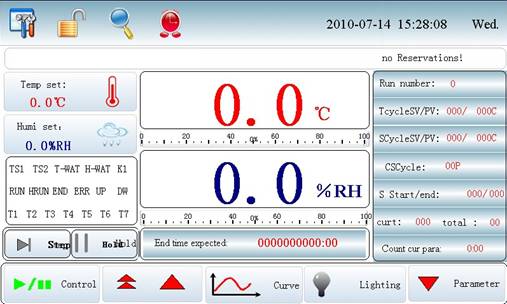

2. English and Chinese LED LCD touch screen controller imported with original packing

3. large electrothermal watch window:

4. Reliable and excellent uniform air supply system

■the top of long axis motor is vertically installed to prevent the main shaft decentralization due to long-term continuous operation.

■the double deflection air supply of imported centrifugal blower can be adjusted according to horizontal and vertical angles to ensure more consistent temperature and humidity uniformity of the cabinet.

5. Stable and reliable water cycle supply system:

■the pipeline design ensures the uniformity of cabinet pressure, water pressure and external atmosphere pressure to prevent vapor leakage.

■ the key parts of water pipeline adopts the production of opening mold to prevent water blocking caused by water pipeline pollution.

6. Two different materials can be selected:

■Atomized stainless steel surface, if the cleaning is frequently made along the lines clean, the completely new appearance of the machine can be maintained,(such an option is recommended)

■Electrostatic spraying surface of high quality (according to customer requirements)

7. The equipments have specialized software which can make one computer control multi testing machine (optional)

8. High quality components and optimized design are adopted to make the lower noise of the machine operation.

|

Type

|

B

|

C

|

D

|

E

|

|

Volume L

|

150

|

225

|

408

|

800

|

1000

|

150

|

225

|

408

|

800

|

1000

|

150

|

225

|

408

|

800

|

1000

|

150

|

225

|

408

|

800

|

1000 |

|

Temperature range

|

-20℃~150℃

|

-40℃~150℃

|

-60℃~150℃

|

-70℃~150℃

|

|

Humidity range

|

|

|

Temperature fluctuation

|

±0.5℃

|

|

Humidity fluctuation

|

±2.5%RH

|

|

Temperature uniformity

|

±1.5℃

|

|

humudity uniformity

|

± 3.0% RH (humidity ≥ 75% RH)

|

|

Temperature rising time

|

In 55 minutes

Rise from -20 ℃ to +150 ℃

|

In 60 minutes

Rise from -40 ℃ to +150 ℃

|

In 70 minutes

Rise from -60 ℃ to +150 ℃

|

In 70 minutes

Rise-40 ℃ to +150 ℃

|

|

Temperature falling time

|

In 20 minutes

Decline from +20 ℃ to -20 ℃

|

In 50 minutes

Decline from+20 ℃ to -40 ℃

|

In 70 minutes

Decline from +20 ℃ to -60 ℃

|

In 60 minutes

Decline from+20 ℃ to -40 ℃

|

|

Nominal internal volume

|

150L (150 type) 225L (225 type) 408L (408 type) 800L (800 type) 1000L (1000 type)

|

|

Internal box size (W × H × D) mm

|

500×600×500 500×750×600 600×850×800 1000×1000×800 1000×1000x1000

|

|

External box size

(W×H×D)mm

|

1000×1530×920 700×1680×1330 800×1780×1380 1200×1930×1380 1200×1930×1830

|

|

Model preparation instruction

|

|

|

Internal box material

|

SUS # 304 stainless steel

|

|

Power supply voltage

|

380V AC 3Φ 3W 50Hz

|

Product advantages:

1. The controller operation uses the fuzzy algorithm, the latest technology control and proper adjustment of refrigeration to make the best results; 7 "TFT true color LCD touch screen is larger than the other screens.

2.The controller interface of humanization design has more convenient operation and more reliable operation.

3. The refrigeration control system adopts cooling demand algorithm to reasonably and effectively use cooling capacity and effectively reduce the mutual consumption of heat and cold so as to achieve control stability and energy saving.

4.The coupling PID adopted by the temperature and humidity control can effectively prevent the sudden run away of the controlled humidity value, which not only makes constant temperature and humidity but also achieves well the function of alternating temperature and humidity .

5.The refrigeration system adopts imported compressor which has the lower noise and better performance.

6. The sampling calculation for a second can ensure the real-time curve sampling and historical data storage for 110 days. The sampling rate can be arbitrarily set from 3 seconds to an hour.

7. Extra long constant time of 99999 hours .

8. The program segment setting time of 540 hours and 59 minutes.

9. There is the USB interface to connect computer and corporate LAN.

● Communication components, auto parts, metal, plastic

●Steam engine vehicle, food industry, pharmaceutical industry, academic and research institution;

Download:

Operation Instruction in Chinese

Operation Instruction in English

Maintenance Instruction of Equipment